MOLDINO - EPDREH-TH3,EPDRH-TH3 : Radius End Mill for Hardened Steel | JSR GROUP

Radius End Mill for Hardened Steel

EPDREH-TH3

EPDRH-TH3

Small-radius deep-milling radius end mill for hardened steel

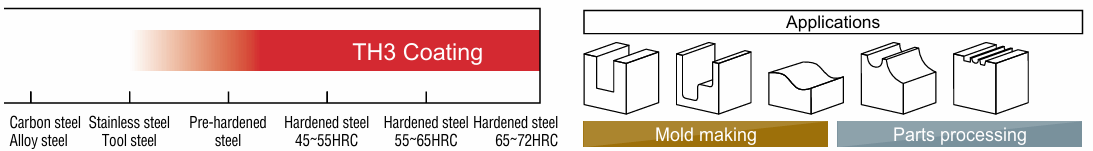

DC8mm to 12mm added to the 4-flute lineup! TH3 Coating benefits and unique cutting edge profile enables long-life/high-accuracy milling of hardened steel.

Features of EPDR(E)H-TH3

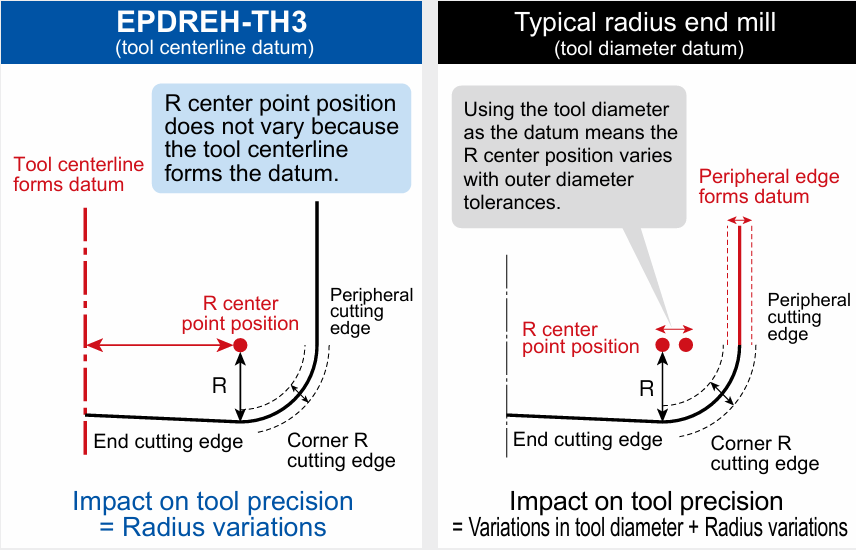

Corner radius precision guaranteed for high-accuracy milling

Tool design optimized for high-accuracy milling

TH3 Coating for milling hardened steel

|

EPDREH-TH3 | ||

| 2 Flutes | φ0.2~φ1 [ 53 Items] (Corner Radius R0.02~R0.2) |

||

| 4 Flutes | φ1~φ6 [266 Items] (Corner Radius R0.02~R1) |

||

| EPDRH-TH3 | |||

| 4 Flutes | φ8~φ12 [26 Items] (Corner Radius R0.2~R2) |

||

| Task | We need high-precision milling. But high-accuracy milling requires measuring the actual tool diameter.And diameter corrections take time. |

| Point | The corner radius of Evolution type uses the tool centerline as its datum independent of the tool diameter. This allows high-accuracy milling compared to conventional tools, even when using nominal diameters. *The corner radius of EPDRH-TH3 (DC8mm~12mm) uses the tool diameter as its datum. |

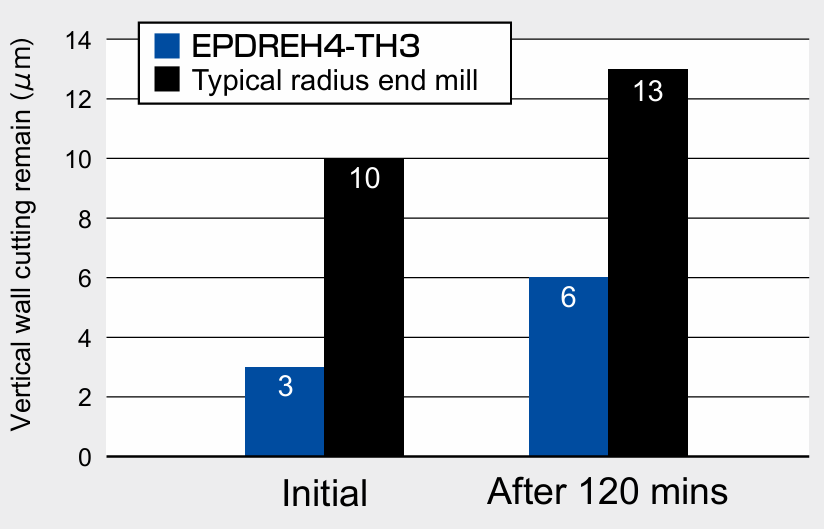

| High-precision corner radius | Comparison between cutting remain for vertical wall milling using nominal diameter | |

|

|

【Cutting conditions】 |

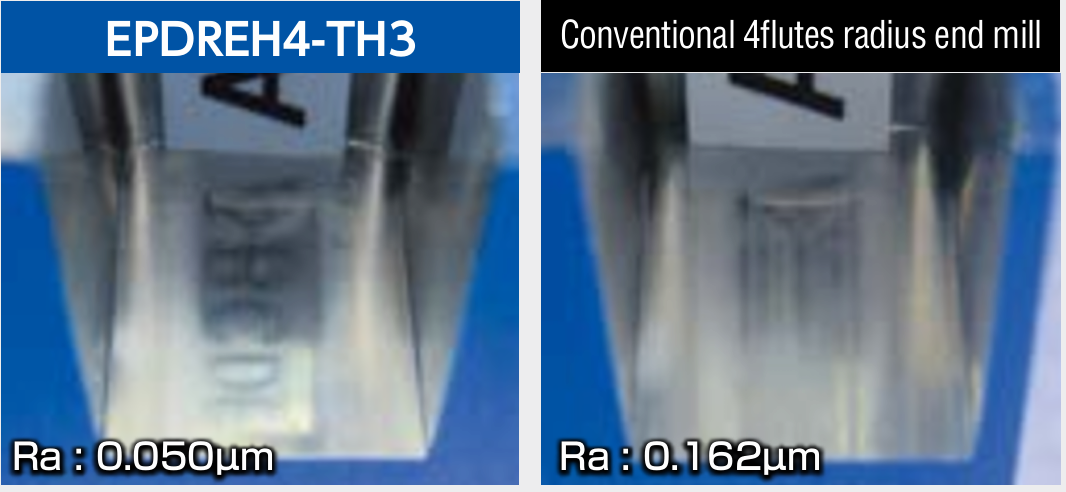

| Task | Machined surface is not smooth enough for finishing of hardened steel.Machined surface is uneven after long time machining then it will take long time for polish. |

| Point | A positive cutting edge profile is adopted for the bottom cutting edge. Thus, improved machined surface quality for hardened steel is achiveved. |

|

Good level of shine for bottom face finishing (“ABCDE” text is reflected) |

【Cutting conditions】 Bottom face finishing Tool dia. : φ3(RE0.1) No. of flutes : 4flutes Cutting speed : vc = 131m/min Feed per tooth : fz = 0.025mm/t Depth of cut : ap × ae = 0.028×0.05mm Work material : STAVAX(52HRC) Coolant : Mist blow |

| Task | We want to switch to automated operation. But with direct milling of hardened steel, we never know when a tool might break. |

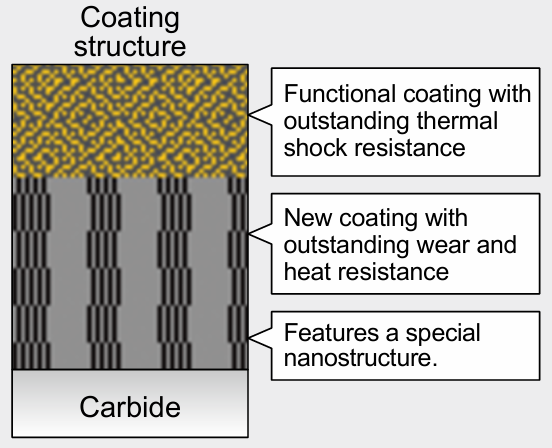

| Point | The tools combine carbide base material designed for hardened steel machining with the TH3 Coating, offering improved wear resistance and allowing longer machining usage over conventional tools! |

| TH3 Coating | Small damage after 11 hours of finish processing | |||

|

Features and performance ・Hard surface coating for outstanding wear and heat resistance Target steel grades ・Hardened steels (especially 50 HRC or higher) ; high-speed steel |

|

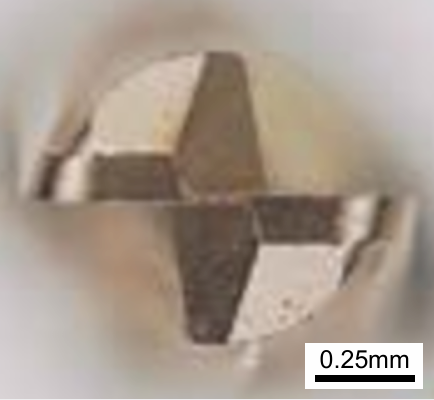

Tool photo after use

Flank wear : 0.005mm |

【Cutting conditions】 Finished surface is posted on page 33 |

|

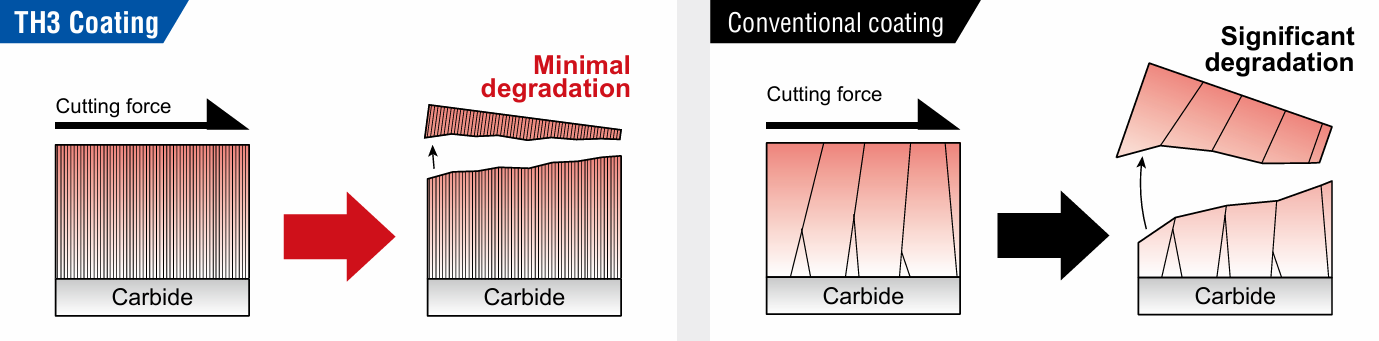

| Point | TH3 features a special nanostructure to minimize degradation of the coating layer! |